- Moulding tool production

- Mechanical cleaning

- Mechanical processing

- Custom production of individual machines

- Commerce

About us

The Noex s.r.o. is present on the Slovakian field since 2014. Its main function is the mechanical cleaning of different metal components, profiles, sheets, pressing tools, furthermore producing, repairing and designing of metal moulding tools, designing of unique machines, machinery trade, service and counselling.

Tool production

Our primary function is the producing of own-designed plastic moulding and cutting tools, but we undertaking the maintenance and upgrade or renewal of completed functioning tools and machines too. We offer complete metal- and plastic industrial solutions.

We producing/repairing the following tools:

- Precision tools

- Heat sensitive moulding tools

- Multi-cavity tools

- Pressure aluminum diecasting

- Cutting/bending/pressing machines/tools

- Prototype tools

On request we also undertaking the producing or repairing of extrusion tools and pressing tools.

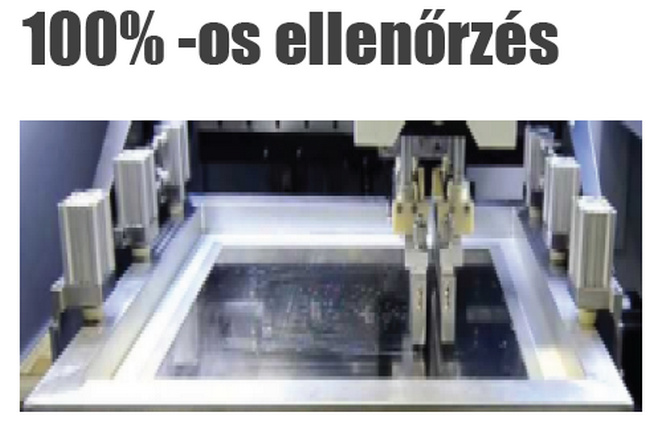

Mechanical cleaning and mechanical processing

With our modern equipments we can deal with mechanical cleanings and mechanical processings like: drilling, milling, punching or cutting to size, furthermore manufacturing of metal parts.

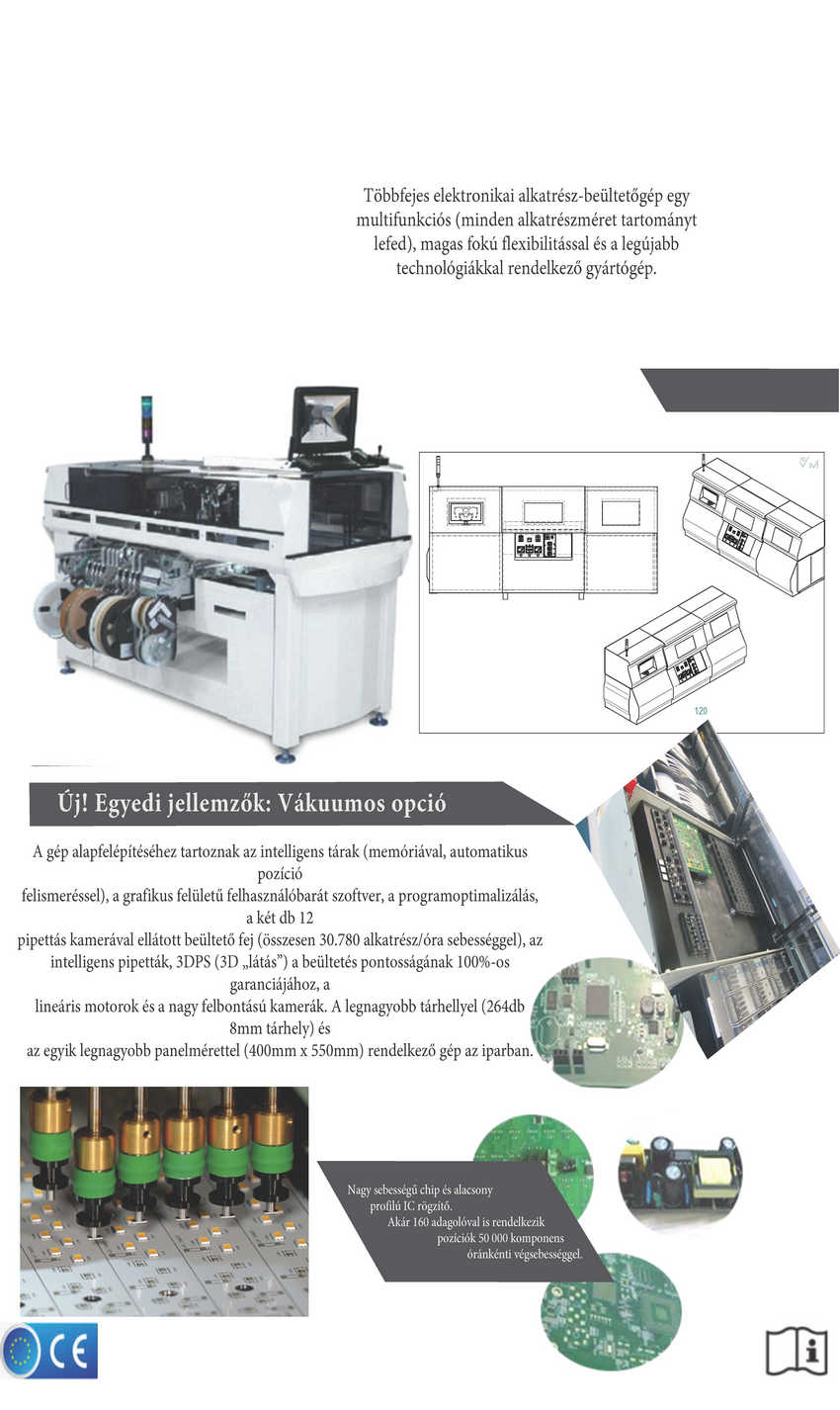

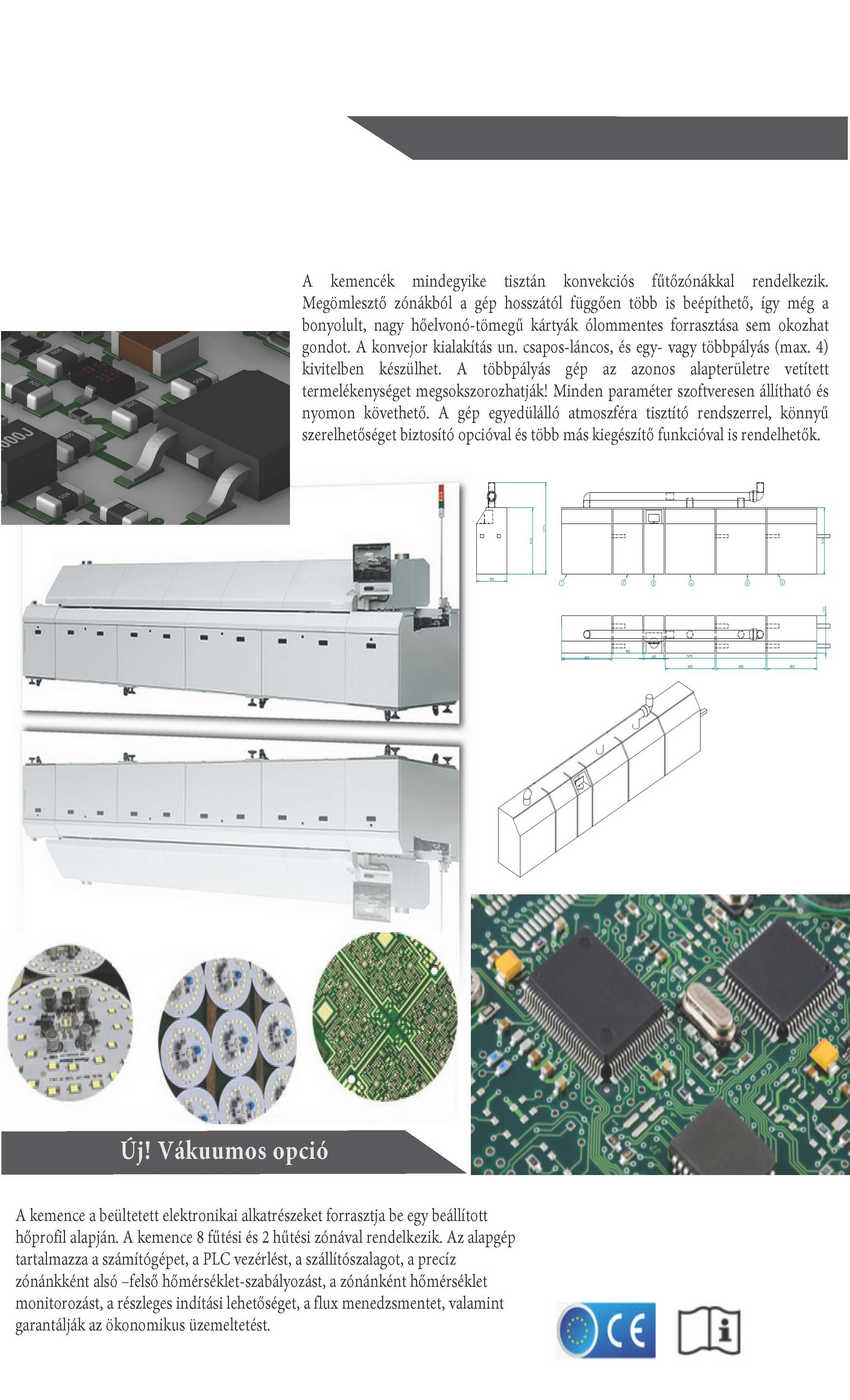

Industrial automation, machine building and trade

We also undertake custom production of different machinery, crane tracks and conveyor belts, technological upgrades, system integration with components of renowed manufacturers. In addition we are in strategic cooperation with multiple companies to provide and manufacture parts and units.

On commercial basis we deal with automatic and semi-automatic machines. We offer complete installation and servicing of our partners machines with installation of custom software on demand. We perform other engineering tasks, such as PLC programming or IT development.

Tool production

Our primary function is the producing of own-designed plastic moulding and cutting tools, but we undertaking the maintenance and upgrade or renewal of completed functioning tools and machines too. We offer complete metal- and plastic industrial solutions.

We producing/repairing the following tools:

- Precision tools

- Heat sensitive moulding tools

- Multi-cavity tools

- Pressure aluminum diecasting

- Cutting/bending/pressing machines/tools

- Prototype tools

On request we also undertaking the producing or repairing of extrusion tools and pressing tools.

Mechanical cleaning and mechanical processing

With our modern equipments we can deal with mechanical cleanings and mechanical processings like: drilling, milling, punching or cutting to size, furthermore manufacturing of metal parts.

Industrial automation, machine building and trade

We also undertake custom production of different machinery, crane tracks and conveyor belts, technological upgrades, system integration with components of renowed manufacturers. In addition we are in strategic cooperation with multiple companies to provide and manufacture parts and units.

On commercial basis we deal with automatic and semi-automatic machines. We offer complete installation and servicing of our partners machines with installation of custom software on demand. We perform other engineering tasks, such as PLC programming or IT development.

Ask for advice and a unique quotation!

Feel free to contact us!

Noex s.r.o.,

Hadovská cesta 5, 945 01 Komárno, Slovakia

E-mail: noexslovakia@gmail.com

Web: www.noexsro.com

Feel free to contact us!

Noex s.r.o.,

Hadovská cesta 5, 945 01 Komárno, Slovakia

E-mail: noexslovakia@gmail.com

Web: www.noexsro.com